Beer brewing at the University of Wrocław

Biotechnologists from the University of Wrocław along with researchers from the Wrocław University of Environmental and Life Sciences and the Wrocław University of Science and Technology have brewed some beer… for scientific purposes, of course.

A team of scientists examined the interior metabolome and profile of volatile organic compounds in barm and its mutants, which produce beer with a better aroma. The effect of the analyses is the publication of an article in Scientific Reports, a highly esteemed magazine published by Springer Nature. Dr Sławomir Jan Jabłoński from the Faculty of Biotechnology, University of Wrocław, a co-author of the article, is telling us about the team’s research.

The volatile compounds are responsible for the pleasant aroma

“Volatile organic compounds are compounds with a high vapour pressure in room temperature, or to put it simply—compounds which vaporise easily. They are also often slightly soluble in water, so they may be extracted easily from an aqueous solution, which is important in the production of consumer articles, such as beer”, dr Jabłoński explains. It is a quite wide class of chemical compounds with various chemical structures. Some of them smell nice, which makes them desirable in consumer articles or cosmetics, while others, on the contrary, have an unpleasant smell. Many of them are produced by living organisms, including plants. Volatile organic compounds are responsible for the pleasant smell of flowers and herbs. They are also produced by yeasts which are researched by the authors of the publication.

Yeasts pose as flowers

The natural living environment of yeasts are fruit skins and plant surfaces. One of the theories suggests that yeasts produce volatile compounds because it facilitates their settling in new places. Of course, yeasts cannot move on their own and they need the aid of insects which are attracted to the smell of volatile compounds. “Yeasts try to lure insects in, just as plants do it, and then attach themselves to their legs and move further with them”, says dr Jabłoński.

Humans have adapted yeasts for the production of fermented preserves. Throughout the centuries, brewers, unaware of the biological processes taking place during beer production, made a selection—for example, getting rid of a batch with an unpleasant smell and leaving the one with an attractive aroma—thus obtaining barm strains producing very intensive volatile organic compounds with a pleasant smell.

Mutagenesis vs. genetic modification

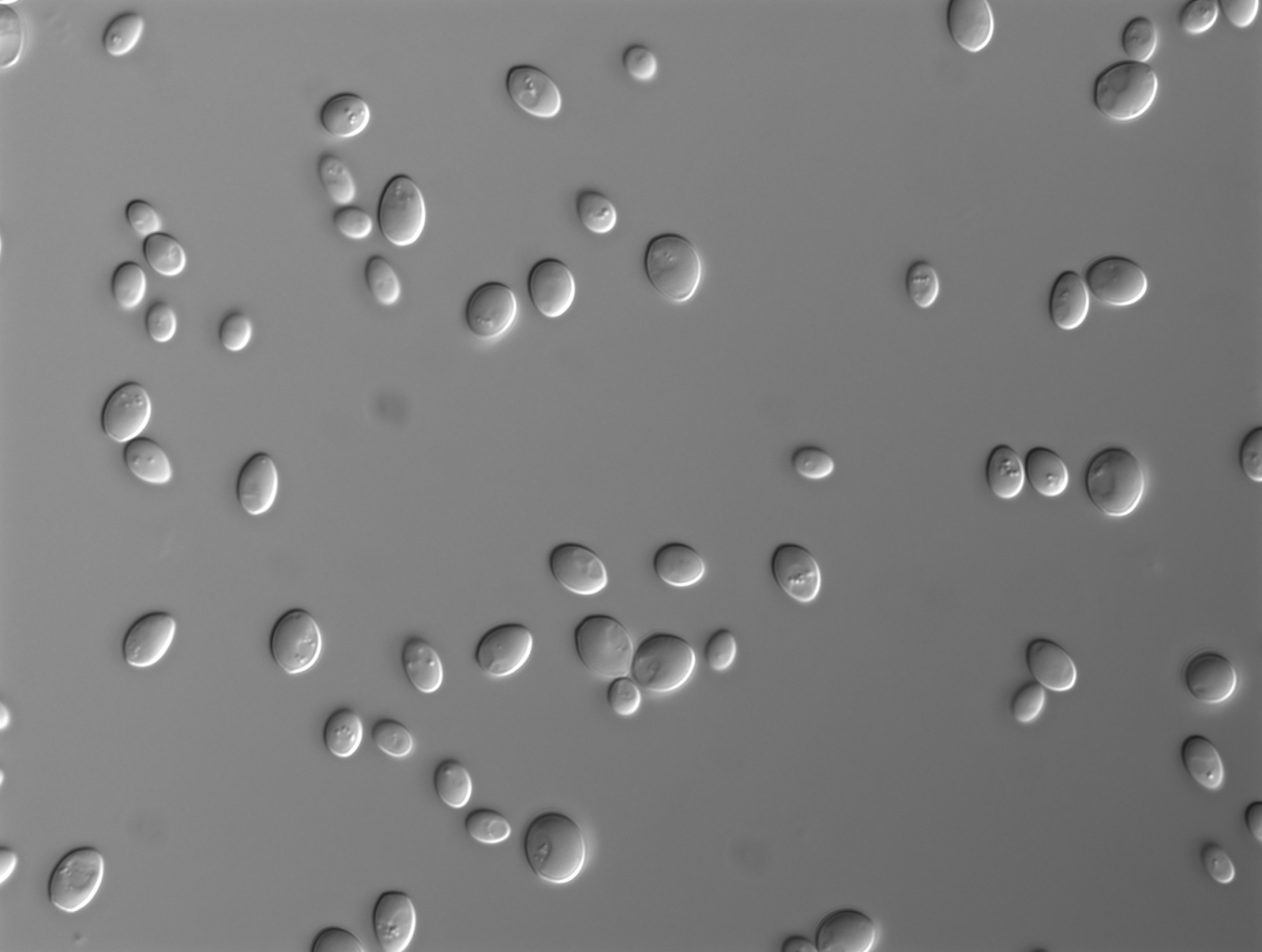

The team examined barm strains produced from two natural yeast strains in UV-induced mutagenesis.

In the process of mutagenesis, the DNA of living organisms, in this case of yeasts, is damaged. An agent causing the damage of genetic matter is used on the liquid yeast suspension. In this case the agent was UV radiation which is relatively safe for the person conducting the experiment. “Only some cells survive the process of mutagenesis, so we cannot predict the exact result”, the biotechnologist explains. “The goal of this part of research was choosing microorganisms which acquired certain features, i.e. the strains producing fragrant volatile compounds, to be precise.”

It is very likely that there will be mutations, i.e. changes within the DNA sequence, in the organisms which survived mutagenesis. If we are only interested in whether a given organism has acquired a desired feature—a pleasant smell in this case—we may stop at this stage. “But we as scientists were interested in the reason behind this feature, we wanted to know what compounds and in what proportions were present in the mutated strains”, dr Jabłoński emphasises.

“In the case of random mutagenesis (e.g. induced by UV radiation), we are only able to determine what changes occurred in the DNA sequence and what was in fact the basis of the mechanism which caused the changes in the properties of a given microorganism, after conducting a series of analyses.”

“In the case of genetic engineering, it is the opposite. We know which fraction of the DNA sequence we want to change and how we want to do it. We hope that making this modification will lead to the creation of a desired feature, i.e. the increase or decrease of production of a given compound. In genetic modification, we use tools which give us much more precise effects than UV radiation.”

The scientist emphasises that the benefits of random mutagenesis result mostly from Polish legal conditions. “In Poland, we have very restrictive laws concerning the industrial use of genetically modified organisms. Mutagenesis also occurs in natural conditions. Yeasts live naturally on plant skins where they are illuminated by sunlight. Since sunlight also contains a UV light component, yeasts undergo a natural process of mutagenesis. This is why this method of acquiring features which are profitable for industry is not disqualified by our legal system.”

Will yeast replace hop?

The scientists from Wrocław identified a large amount of terpenoids—volatile aromatic compounds which in traditional beer brewing derive mostly from hop—in the mutated yeast strains. This discovery may have important implications for both the brewing and cosmetic industry. Climate change influences hop crops, modifying their organoleptic parameters, which may have a negative impact on product quality. Sourcing terpenoids from yeasts might be an alternative. The metabolic pathway which leads to the biosynthesis of terpenoids is complex and comprises several stages. Its purpose is the synthesis of lipids, the key ingredients of cell membranes. “However, the reaction intermediates might be the precursors of volatile compounds, including those which are characterized by desirable aromatic features”, dr Jabłoński explains. As shown in the research featured in scientific papers, these compounds may be derived from yeasts with the aid of genetic engineering through the implementation of a gene coding an enzyme, which enables the synthesis of the aromatic compounds found typically in hop.

Vanilla cheesecake flavoured beer

Knowing that placing a genetically modified organism on the Polish market would be problematic, the scientists began to wonder if it was possible to obtain terpenoid-generating yeast strains through the means of random mutagenesis. The analyses they conducted proved that some mutated strains indeed do produce such volatile compounds. The strains which they described in the article produce terpenoids characterised by a flowery and fruity smell, so the beer produced using them would be a rather niche product. “Not every consumer would enjoy beer which smells of vanilla cheesecake, but terpenoids with this scent can definitely be used in the cosmetic industry. Moreover, there is a chance that if we continue the selection, we may obtain a new portion of mutants which would produce terpenoids with a smell more characteristic of beer—which so far has been obtained from hop”, the biotechnologist says.

Metabolic pathways, or the constant compounding of sugars

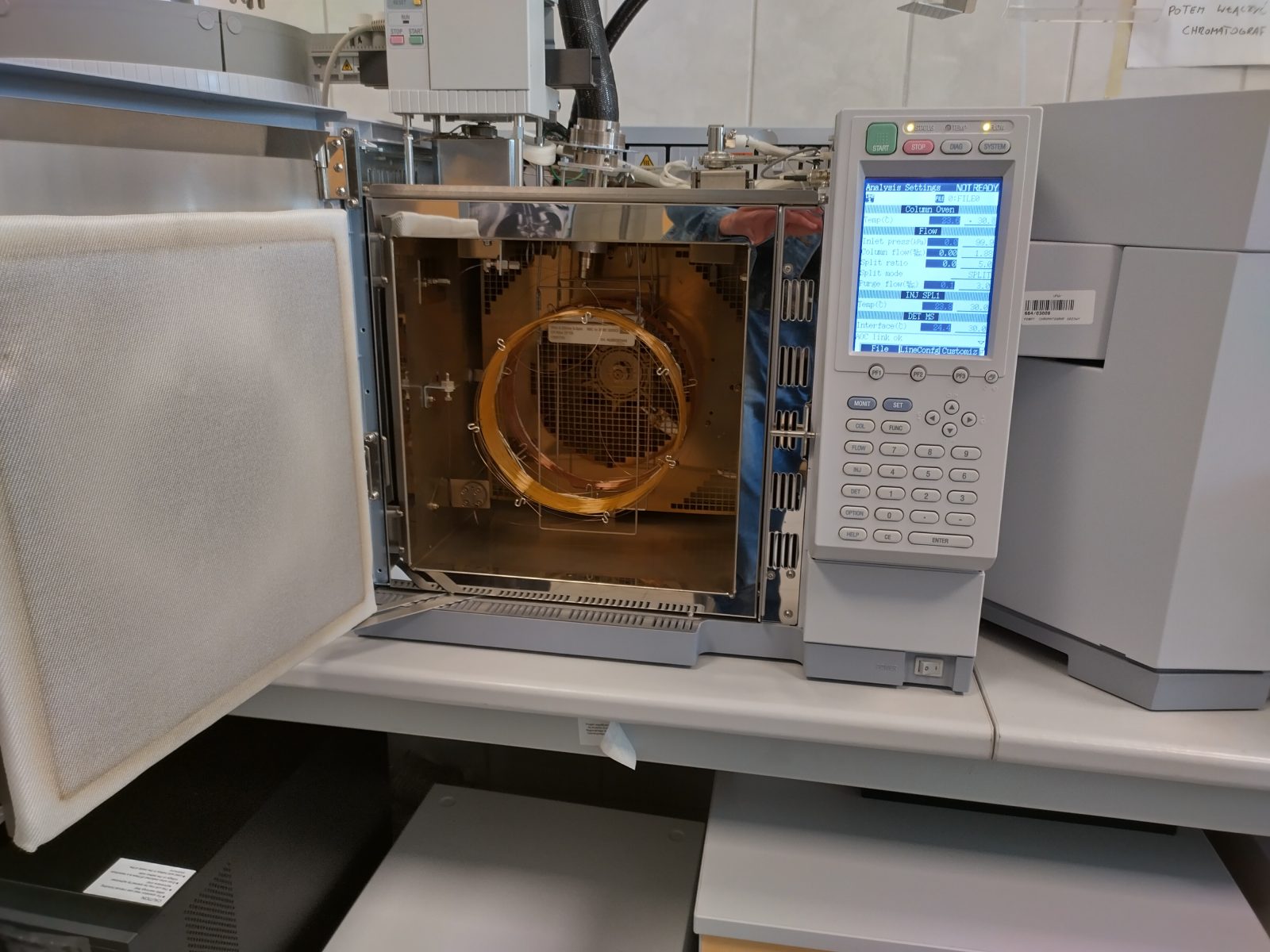

The team conducted a chemical analysis of the fragrances produced by yeasts obtained through mutagenesis. They also analysed what changed in the metabolic pathways of some yeast strains as a result of mutagenesis. A metabolic pathway is a series of chemical reactions most frequently catalysed by enzymes in a living organism, which lead to a transformation of one chemical compound into another. For sugar to transform into a terpenoid, the cell must conduct several chemical reactions along the way. “We have a certain model which describes that. We wondered what changes occurred on the metabolic pathway as a result of the mutations implemented during mutagenesis, which caused the sudden emergence of a previously non-existent chemical compound or its disappearance”, says dr Jabłoński. Metabolites are compounds produced by living organisms. Some of them are excreted from the cell, and others are transformed by it into different compounds as a result of a series of consecutive chemical reactions. Sugar (e.g. glucosis) is transformed into one compound, then another, and another, etc. Finally, we receive a compound which may be excreted by the cell. To tell if something in the metabolic pathway got broken or to find out what changed, we may try to measure the concentration of its intermediate substances. “This was our next step”, he adds. This part of research was conducted in collaboration with the department of dr Piotr Młynarz at the Wrocław University of Science and Technology. The analyses were conducted with the aid of NMR (Nuclear Magnetic Resonance) spectroscopy which enables the identification of individual substances in the mixture, thus making it possible to determine the concentration of intermediate compounds in cells destroyed during mutagenesis. “The mutated yeast strains contain different concentrations of volatile compounds (metabolites)—there may be more or less of them, new ones may appear, while others are absent. Having the information on the concentration of intermediate metabolites, we may start wondering what really happened later.”

It is not a waste, but a choice of the cell

Some volatile compounds emerge from the same metabolic pathway which is used by the cell to produce hydrophobic amino acids. Amino acids are ingredients of proteins. “The cell makes a choice—it can create an amino acid out of sugar and use it to build proteins or it can transform an intermediate metabolite into a nice-smelling volatile compound”, dr Jabłoński explains. It could seem that the creation of a volatile compound is an unnecessary prodigality for the cell, but if it is to ensure the cell’s movement into a new ecological niche, it does not have to be seen as a waste of resources.

What conclusions did the scientists draw after measuring the concentration of intermediate substances? “As we described in our article, the increased production of volatile compounds obtained together with amino acids may probably result from the fact that the mechanism of amino acid synthesis got dysregulated. Thanks to that a larger stream of metabolites is transformed into volatile compounds”, dr Jabłoński summarises.

The team’s research plans

The analyses do not stop here. The next step is sequencing of the DNA of the obtained yeast strains. Once we know the genome sequence, the image of the metabolic pathway will be complemented by the information about enzymes—elements which catalyse particular reactions. On the basis of the genome sequence the scientists will be able to tell which enzymes got damaged or which ones can be produced more, which will give us a full picture of what is left in the mutated cells.

Why are we searching for this information? Dr Jabłoński explains: “If we improve the metabolic model of yeasts, i.e. have better knowledge about the way the metabolism is regulated, we will be able to modify the yeasts with the aid of genetic engineering in such a way that will enable us to use them in the production of aromatic compounds, for example in the cosmetic industry. The GMO restrictions have no application in the production of materials used in cosmetic production because it does not entail the use of whole yeasts—only the retrieved and refined aromatic compound they produce.

Are there any chances to commercialize the strains?

The mutated yeast strains acquired in the process of mutagenesis have substantial commercial potential. The beer with a unique aromatic profile combining flower and fruit undercurrents, produced for research purposes by the Wrocław scientists, could be an interesting innovation on the brewing market, currently dominated by lagers. Launching such a product could significantly broaden the market offer, attracting consumers who seek new gustatory sensations. The aromatic volatile compounds produced by yeast strains acquired during the research could also be applied in the cosmetic industry. However, as dr Jabłoński admits, rather than commercialisation, the team is more interested in basic research in biochemistry and filling in the gaps in this field, i.e. further research on the metabolic pathways of yeasts.

Authors of the paper:

- dr Sławomir Jan Jabłoński, Department of Biotransformation, Faculty of Biotechnology, University of Wrocław

- prof. dr hab. Marcin Łukaszewicz, Department of Biotransformation, Faculty of Biotechnology, University of Wrocław

- dr inż. Karolina Anna Mielko-Niziałek, Department of Biochemistry, Molecular Biology and Biotechnology, Faculty of Chemistry, Wrocław University of Science and Technology

- prof. dr hab. Piotr Młynarz, Department of Biochemistry, Molecular Biology and Biotechnology, Faculty of Chemistry, Wrocław University of Science and Technology

- dr Przemysław Leszczyński Department of Fermentation and Cereals Technology, Faculty of Biotechnology and Food Science, Wrocław University of Environmental and Life Sciences

- mgr inż. Alan Gasiński, Department of Fermentation and Cereals Technology, Faculty of Biotechnology and Food Science, Wrocław University of Environmental and Life Sciences

- prof. dr hab. inż. Joanna Kawa-Rygielska, Department of Fermentation and Cereals Technology, Faculty of Biotechnology and Food Science, Wrocław University of Environmental and Life Sciences

Links to the paper:

https://doi.org/10.1038/s41598-024-64899-4

https://www.nature.com/articles/s41598-024-64899-4

Interviewer: Ewelina Kośmider

Date of publication: 2.10.2024

Translated by Natalia Tkaczuk (student of English Studies at the University of Wrocław) as part of the translation practice.